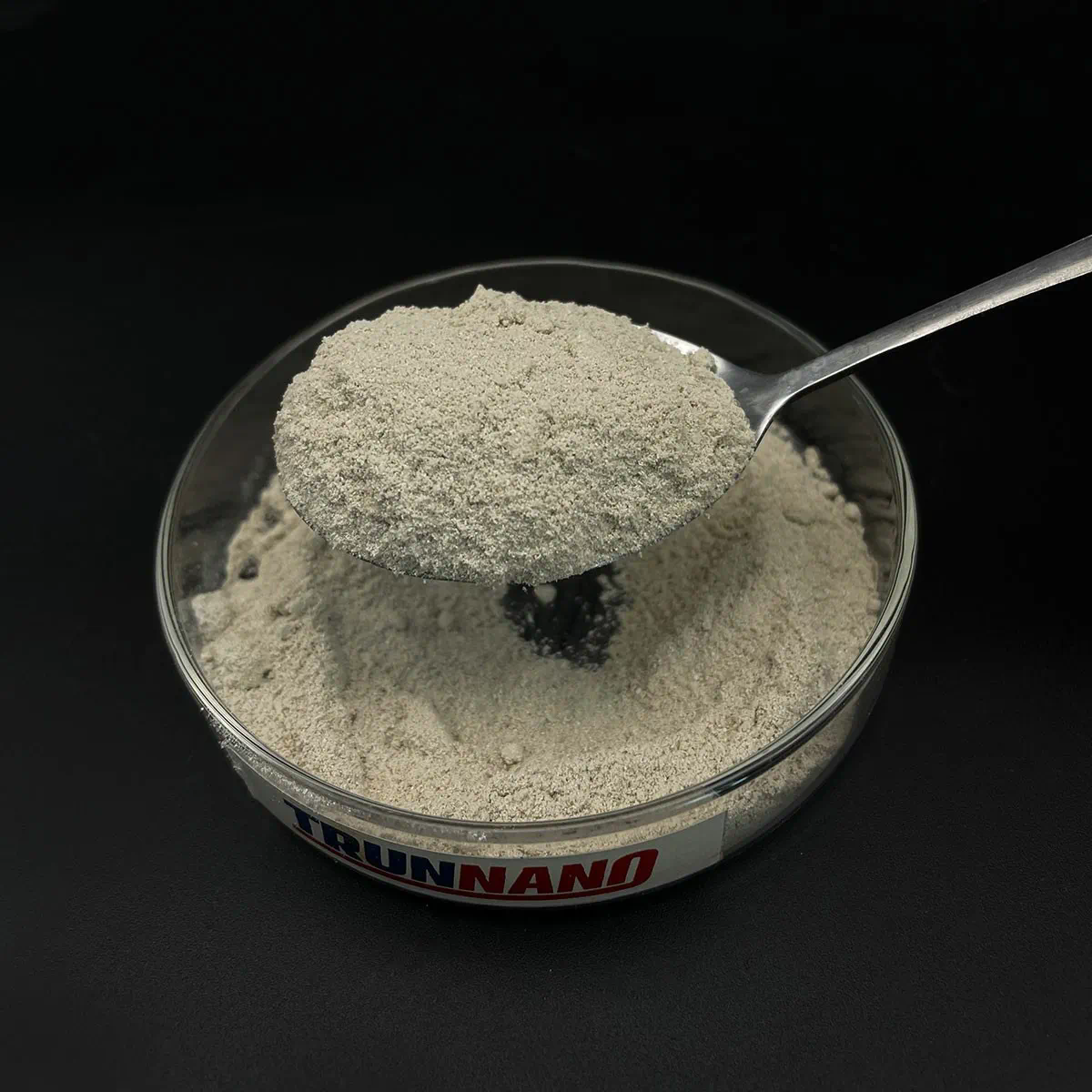

Nanodiamond powder is emerging as a cutting-edge material that is revolutionizing the manufacturing of high-precision tools. This innovative material, comprised of tiny diamond particles measuring just a few nanometers in size, offers unparalleled benefits and applications across various industries. In this article, we will explore the unique properties of nanodiamond powder, its production methods, and its extensive applications in the realm of high-precision tools.

Nanodiamonds are a form of carbon that has unique properties due to their nanoscale size and high surface area. They are created through various methods, including detonation, chemical vapor deposition (CVD), and laser ablation. Each method produces nanodiamonds with different characteristics, which can be tailored for specific applications. The most prevalent method for producing nanodiamonds is via detonation, which involves detonating an explosive material in a controlled environment. This process results in the formation of nanodiamonds along with other carbonaceous byproducts.

One of the standout features of nanodiamond powder is its exceptional hardness. Diamonds are already known for their hardness, but when reduced to the nanoscale, the properties can become even more advantageous. The hardness of nanodiamonds makes them ideal for applications where wear resistance is crucial, such as in cutting tools and abrasives. These tools can maintain their sharpness and effectiveness over longer periods, leading to increased productivity and reduced costs in manufacturing processes.

In addition to their impressive hardness, nanodiamonds possess excellent thermal conductivity. This property is vital in high-precision tools that generate heat during operation. By incorporating nanodiamonds into tool designs, manufacturers can improve heat dissipation, ensuring that tools remain at optimal temperatures and maintain their structural integrity even under intense conditions. This helps to prevent tool failure and prolongs the lifespan of cutting instruments, making them more reliable and cost-effective.

The incorporation of nanodiamond powder into high-precision tools also enhances their lubricating properties. When used as a coating or additive, nanodiamond particles can create a self-lubricating effect, reducing friction between the tool and Graphene the material being processed. This not only improves the performance of the tool but also minimizes wear on both the tool and the workpiece, leading to better surface finishes and precision in machining operations.

Moreover, nanodiamonds exhibit unique electronic properties that can be leveraged in the design of specialized tools. Their semiconductor-like behavior allows for the development of tools capable of sensing changes in temperature, pressure, or other environmental factors. This ability to monitor conditions in real-time is particularly beneficial in high-precision machining, where even minor variations can significantly affect the quality of the final product. By integrating nanodiamonds into sensors or smart tools, manufacturers can enhance control over their processes and improve overall efficiency.

The versatility of nanodiamond powder extends beyond traditional cutting tools. In the realm of advanced manufacturing, nanodiamonds are being explored for use in composite materials. By adding nanodiamond powder to polymer matrices or metals, manufacturers can produce lightweight yet incredibly strong materials. These composites can be used in aerospace, automotive, and medical applications, where strength-to-weight ratios are critical. The incorporation of nanodiamonds into these materials not only enhances mechanical properties but also contributes to improved durability and resistance to wear.

As industries continue to push for higher precision and efficiency, the demand for advanced materials like nanodiamond powder is expected to grow. Manufacturers are increasingly recognizing the potential of nanodiamonds to meet these demands, leading to ongoing research and development efforts aimed at optimizing their properties and applications. Collaborative efforts between researchers and industry professionals are driving innovation in this field, resulting in new formulations and techniques that leverage the unique characteristics of nanodiamonds.

In conclusion, nanodiamond powder is a cutting-edge material that holds immense potential for high-precision tools across various industries. Its exceptional hardness, thermal conductivity, lubricating properties, and unique electronic characteristics make it an ideal candidate for enhancing tool performance and longevity. As research continues to advance and new applications are discovered, nanodiamonds are poised to play a pivotal role in the future of precision manufacturing. The integration of this innovative material into tool design and production processes is not just a trend but a significant leap toward achieving higher efficiency and precision in modern manufacturing.

https://inorthshore.com/