Molybdenum disulfide (MoS2) is a remarkable material known for its exceptional lubricating properties, especially under extreme conditions. This article delves into the properties, applications, and mechanisms of MoS2 as a lubricant, highlighting its significance in various industries.

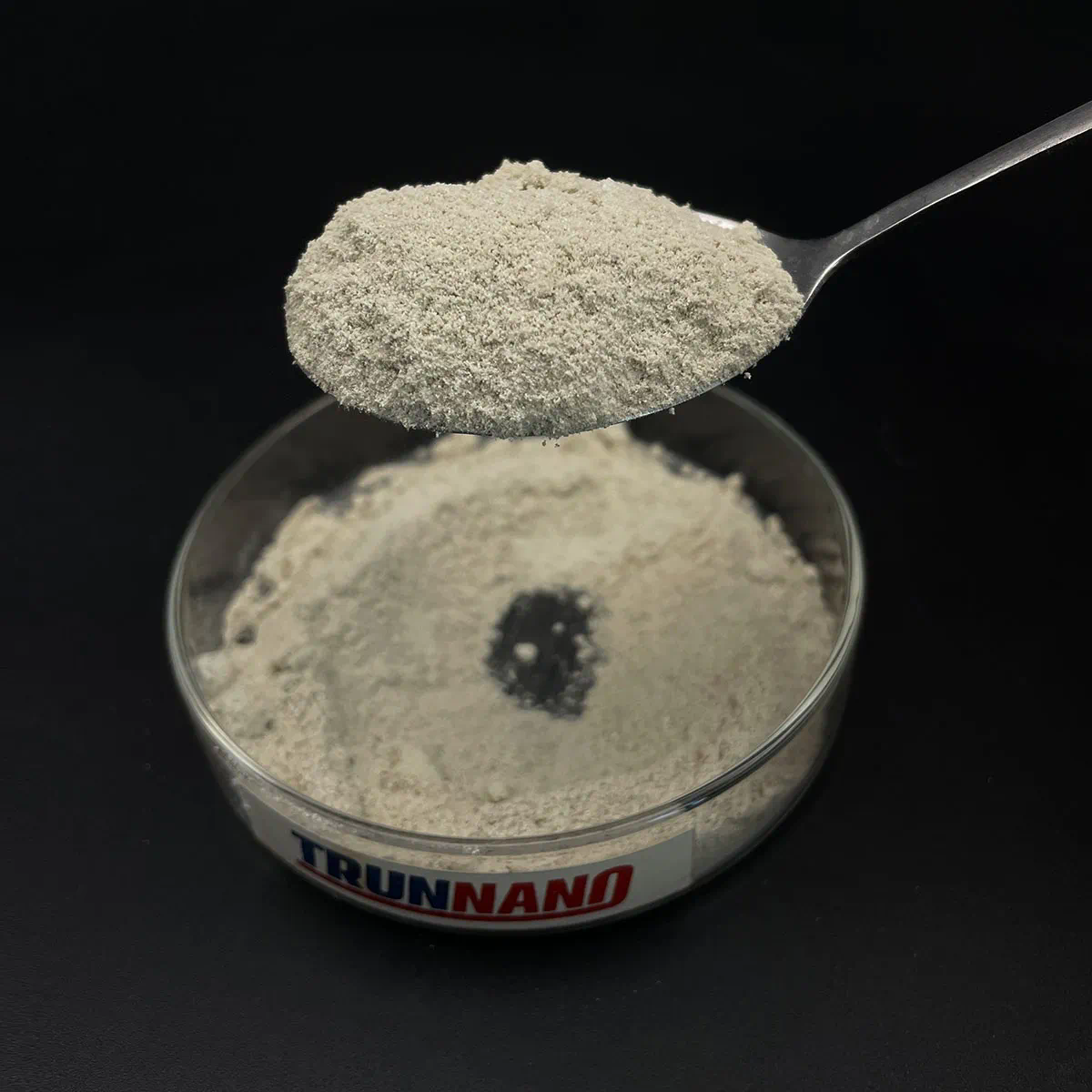

p Molybdenum disulfide is a transition metal dichalcogenide that naturally occurs in a layered structure. Each layer consists of molybdenum atoms sandwiched between two layers of sulfur atoms. This unique arrangement allows the layers to slide over one another with minimal friction, making it an ideal solid lubricant.

p The excellent performance of MoS2 as a lubricant is attributed to several key characteristics. Firstly, it has a low coefficient of friction, which remains consistent even under high loads and temperatures. Secondly, it can withstand extreme pressure, making it suitable for heavy machinery operating under demanding conditions. Finally, MoS2 is chemically inert, meaning it does not react with most substances, further enhancing its stability and longevity as a lubricant.

h2 Properties of Molybdenum Disulfide

p The physical and chemical properties of MoS2 contribute significantly to its effectiveness as a lubricant. Its layered structure not only facilitates lubrication but also provides resilience against wear and tear. The material exhibits a hardness of about 1-2 on the Mohs scale, allowing it to endure substantial mechanical stress without degrading.

p Another crucial property is its thermal stability. MoS2 can function effectively at temperatures exceeding 300 degrees Celsius in vacuum conditions, and even higher temperatures in inert environments. This characteristic makes it particularly useful in aerospace, automotive, and industrial applications where temperature fluctuations are common.

h3 Mechanisms of Lubrication

p The lubrication mechanism of MoS2 involves several processes, primarily based on its layered structure. When MoS2 is applied to a surface, it forms a lubricating film. As the surfaces move relative to each other, the layers of MoS2 slide over one another, effectively reducing friction.

p Additionally, MoS2 can embed itself into the surface of a material, providing a protective barrier that prevents direct contact between surfaces. This embedding effect is particularly beneficial in applications where traditional liquid lubricants might fail due to evaporation or degradation.

h2 Applications of Molybdenum Disulfide

p MoS2 finds application across various industries, including automotive, aerospace, manufacturing, and electronics. In automotive applications, MoS2 is often used in engine oils and greases to enhance performance and reduce engine wear. It is particularly valuable in high-performance engines, where traditional lubricants may struggle to maintain efficacy under extreme conditions.

p In the aerospace sector, MoS2 is utilized in bearings, gears, and other components exposed to high pressures and varying temperatures. Its ability to maintain performance in a vacuum makes it ideal for spacecraft and satellite applications, where conventional lubricants would evaporate or degrade.

h3 Industrial Uses

p The manufacturing industry benefits from MoS2’s unique properties as well. It is commonly used in machining and metal forming processes, where it acts as a dry lubricant to reduce friction and wear on tools. The use of MoS2 can lead to improved tool life and better surface finishes, resulting in cost savings and enhanced productivity.

p Furthermore, MoS2 is gaining traction in the electronics industry, particularly in the fabrication of microelectromechanical systems (MEMS). Its lubrication properties help in preventing stiction, a common issue where moving parts adhere together, causing malfunction.

h2 Environmental and Health Considerations

p While MoS2 is favored for its performance, it is essential to consider environmental and health aspects. Unlike many traditional lubricants, MoS2 is non-toxic and environmentally friendly. Its use can reduce the reliance on petroleum-based lubricants, contributing to more sustainable practices in various industries.

p However, proper handling and disposal are necessary to minimize any potential environmental impact. As with any material, dust generated from MoS2 can be harmful if inhaled, so safety measures should be implemented during its use and application.

h3 Future Trends in Molybdenum Disulfide Research

p As technology evolves, so do the applications and methods of utilizing MoS2. Ongoing research is focused on enhancing its properties through nanostructuring and composites. By integrating MoS2 with other materials, researchers aim to develop hybrid lubricants that can perform even better under extreme conditions.

p Additionally, advancements in material science are leading to innovative ways to synthesize MoS2, making it more accessible and cost-effective. These developments could broaden its application scope, potentially leading to new markets and uses in various fields.

h2 Conclusion

p Molybdenum disulfide stands out as an invaluable material for lubrication in extreme conditions. Its unique properties, coupled with its versatility across multiple industries, underline its significance in modern engineering and technology. As research progresses, the potential applications of MoS2 continue to expand, promising exciting developments for the future of lubrication technology.

p Through understanding MoS2’s MoDTP Cas No.:72030-25-2 mechanisms, applications, and properties, industries can leverage this exceptional material to enhance performance, reduce wear, and embrace more sustainable practices. The future of lubrication in extreme conditions looks promising, with Molybdenum disulfide at the forefront of innovation.

https://inorthshore.com/