Flexible Busbar Machines: Adapting to the Changing Needs of Electrical Systems

With the rapid advancement in technology, electrical systems are constantly evolving. The demand for more flexible and efficient solutions is increasing, pushing the boundaries of traditional manufacturing processes. One such example is the emergence of flexible busbar machines, which have revolutionized the production of busbars for electrical systems. In this article, we will explore the benefits and applications of flexible busbar machines and how they are adapting to the changing needs of electrical systems.

Flexible busbars are an essential component of electrical systems as they provide a reliable and efficient means of conducting electricity. Traditionally, busbars were made using rigid copper or aluminum bars, which required extensive manual labor and complex assembly processes. However, with the introduction of flexible busbar machines, the production process has become faster, easier, and more cost-effective.

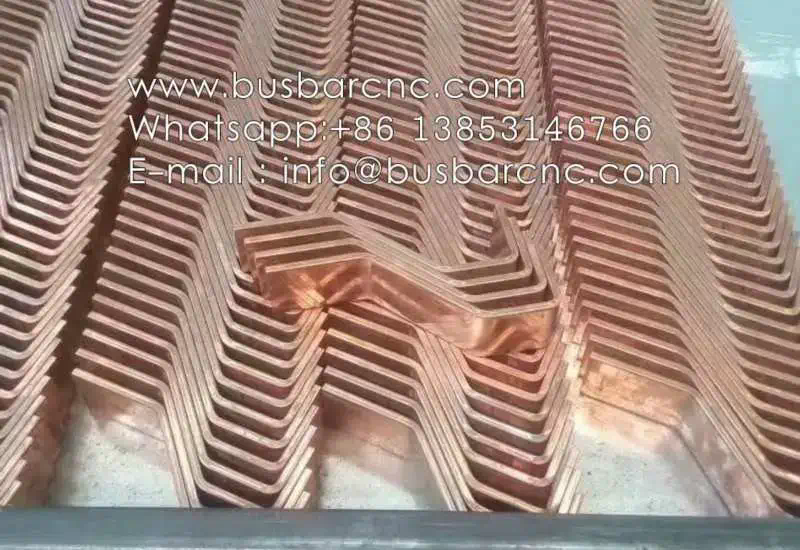

One of the key advantages of flexible busbar machines is their ability to produce busbars of various shapes and sizes. Unlike rigid busbars, which are limited to straight or slightly curved designs, flexible busbars can be easily bent, twisted, or molded into any desired shape. This flexibility allows for better utilization of available space, especially in compact electrical panels or tight enclosures.

Furthermore, the automated nature of these machines ensures consistent quality and accuracy in the production process. By eliminating the need for manual bending or cutting, flexible busbar machines reduce the risk of human errors and ensure precise dimensions and alignments. This not only improves the overall performance of the electrical system but also reduces the likelihood of malfunctions or accidents.

In addition to their flexibility and precision, flexible busbar machines offer significant time and cost savings. The automated production process allows for faster production rates, reducing the overall manufacturing time. Moreover, the elimination of manual labor reduces labor costs and minimizes the chances of injuries or fatigue-related errors. These cost and time savings make flexible busbar machines an attractive option for manufacturers looking to improve their production efficiency.

The applications of flexible busbar machines are wide-ranging. They are commonly used in power distribution systems, such as electrical substations or switchgear panels, where space limitations and complex layouts require customized busbars. The flexibility of these machines allows for efficient utilization of available space, ensuring optimal performance and reliability of the electrical system.

Moreover, flexible busbar machines also find applications in renewable energy hydrolic busbar shear systems, such as solar or wind power installations. These systems often require intricate and compact designs to maximize energy generation in limited spaces. Flexible busbars can be easily customized to fit the unique requirements of these systems, enabling efficient energy transfer and reducing power losses.

In conclusion, flexible busbar machines have emerged as a game-changer in the production of busbars for electrical systems. Their ability to produce flexible and customized busbars has revolutionized the industry, offering improved efficiency, cost savings, and better performance. As technology continues to evolve, the demand for more flexible and adaptable solutions will only increase. Flexible busbar machines are well-positioned to meet these changing needs, making them an integral part of modern electrical systems.

Flexible Busbar Machines: Adapting to the Changing Needs of Electrical Systems

With the rapid advancement in technology, electrical systems are constantly evolving. The demand for more flexible and efficient solutions is increasing, pushing the boundaries of traditional manufacturing processes. One such example is the emergence of flexible busbar machines, which have revolutionized the production of busbars for electrical systems. In this article, we will explore the benefits and applications of flexible busbar machines and how they are adapting to the changing needs of electrical systems.

Flexible busbars are an essential component of electrical systems as they provide a reliable and efficient means of conducting electricity. Traditionally, busbars were made using rigid copper or aluminum bars, which required extensive manual labor and complex assembly processes. However, with the introduction of flexible busbar machines, the production process has become faster, easier, and more cost-effective.

One of the key advantages of flexible busbar machines is their ability to produce busbars of various shapes and sizes. Unlike rigid busbars, which are limited to straight or slightly curved designs, flexible busbars can be easily bent, twisted, or molded into any desired shape. This flexibility allows for better utilization of available space, especially in compact electrical panels or tight enclosures.

Furthermore, the automated nature of these machines ensures consistent quality and accuracy in the production process. By eliminating the need for manual bending or cutting, flexible busbar machines reduce the risk of human errors and ensure precise dimensions and alignments. This not only improves the overall performance of the electrical system but also reduces the likelihood of malfunctions or accidents.

In addition to their flexibility and precision, flexible busbar machines offer significant time and cost savings. The automated production process allows for faster production rates, reducing the overall manufacturing time. Moreover, the elimination of manual labor reduces labor costs and minimizes the chances of injuries or fatigue-related errors. These cost and time savings make flexible busbar machines an attractive option for manufacturers looking to improve their production efficiency.

The applications of flexible busbar machines are wide-ranging. They are commonly used in power distribution systems, such as electrical substations or switchgear panels, where space limitations and complex layouts require customized busbars. The flexibility of these machines allows for efficient utilization of available space, ensuring optimal performance and reliability of the electrical system.

Moreover, flexible busbar machines also find applications in renewable energy systems, such as solar or wind power installations. These systems often require intricate and compact designs to maximize energy generation in limited spaces. Flexible busbars can be easily customized to fit the unique requirements of these systems, enabling efficient energy transfer and reducing power losses.

In conclusion, flexible busbar machines have emerged as a game-changer in the production of busbars for electrical systems. Their ability to produce flexible and customized busbars has revolutionized the industry, offering improved efficiency, cost savings, and better performance. As technology continues to evolve, the demand for more flexible and adaptable solutions will only increase. Flexible busbar machines are well-positioned to meet these changing needs, making them an integral part of modern electrical systems.

https://inorthshore.com/