Whether you're a newcomer or looking to refine your 3D printing setup, it is crucial to configure your 3D printer correctly.

Listed below are the nine steps in this step-by-step guide to setting up your 3D printer correctly:

1. Identify What Kit You Own

Start by identifying what type of 3D printing kit you own. There are generally three styles of 3D printer kits to consider: pre-assembled, partially assembled, and DIY printer kits. Pre-assembled kits are the easiest to get started with as they come ready to use straight out of the box. Partially assembled kits offer a middle-ground option. These kits are usually divided into components to save space during shipping. DIY kits represent the most hands-on approach. These kits require substantial assembly, and you'll likely spend more time constructing the printer from the ground up.

2. Read and Follow the Assembly Instructions

After you’ve identified the 3D printer kit you own, it’s important to carefully read the assembly instructions. Whether you're dealing with a pre-assembled, partially assembled, or DIY kit, taking the time to understand the setup process up front is very important. Reading instructions carefully, organizing components, and executing assembly steps accurately not only reduces the need for later adjustments but also ensures safe and reliable performance. So, before you dive into making connections or printing, prioritize reading and following the instructions diligently. It's the key to hassle-free 3D printing.

3. Check To See if Everything Is Level and Square

If your printer came pre-assembled you’ll only need to plug in a few extensions and pieces of equipment. After you've assembled the printer, you’ll want to check that everything is level and square. This is important for precise filament deposition and successful object construction. This leveling process can vary between machines, with options for both manual and automatic adjustments. Ensuring a level build platform is very important because any significant gap between the print bed and the nozzle can result in poor adhesion of the critical initial layer, leading to an automatic print failure.

To level your 3D printer bed, you can either use an auto bed leveling (ABL) sensor or manually level the bed. ABL measures the distance between the nozzle and the build surface and requires a firmware update for translation. For the exact process, follow your printer instructions carefully as this will vary depending on the manufacturer.

4. Assume Your Printer Is Not Calibrated

Assuming that your printer is calibrated could lead to a costly exercise as it will result in a lot of filament being wasted. Calibrating your 3D printer is the key to consistently producing high-quality prints. Your instruction manual typically includes a section dedicated to calibration instructions. Follow the calibration instructions provided with your printer to fine-tune settings such as: nozzle height, bed leveling, and axis alignment. Failing to do so can result in prints that are skewed, misshapen, or fail altogether.

5. Lubricate Everything Well

Proper lubrication is crucial for the numerous moving components to keep your 3D printer running smoothly. If a part interacts with another surface, it likely requires lubrication, but the specific lubricant depends on the component's function.

For instance, components like the threaded rod and nut along the Z-axis, responsible for adjusting the printer nozzle's height, demand lubrication. The X- and Y-axis guide rails, guiding the printhead and bed, also benefit from proper lubrication. This not only ensures a trouble-free printing process but also prolongs the life of the printer's parts.

When selecting a lubricant for your 3D printer, consider its ability to protect against wear and facilitate smooth component movement. Consult your owner's manual or setup instructions to determine the right lubrication and maintenance schedule. It's advisable to perform a pre-print check by manually moving the printhead and other components to ensure smooth operation.

6. Set the Preferred Print Speed

Print speed dictates how rapidly the 3D printer's extruder moves while depositing material. It is typically measured in millimeters per second (mm/s) or millimeters per minute (mm/min). The choice of print speed involves a trade-off between print quality and efficiency. Slower print speeds tend to yield higher-quality prints, allowing for precise material deposition and better adhesion between layers. Conversely, higher speeds may compromise print quality, especially for intricate details. Material compatibility is another critical consideration, as different filaments have specific speed ranges for optimal results. Additionally, print speed affects cooling and, consequently, overall print time. Striking the right balance between speed and quality is key. This is typically guided by the manufacturer's recommendations and fine-tuned through experimentation to achieve desired results while optimizing print duration.

7. Filament Should Be Fed Into the Extruder

Before initiating the printing process, it's essential to prepare the extruder for filament extrusion. This procedure commences with heating the hot end to the specific melting temperature of the filament, which typically exceeds 175 °C. This can vary, however, depending on the filament type. Subsequently, you'll introduce the filament into the heated extruder. Many 3D printers come equipped with pre-configured operations that guide you through this filament-loading process.

It’s important to select the right filament for the project you are working on. Filaments designed for 3D printing typically come in two primary diameters: 1.75 mm and 3 mm (or 2.85 mm). In addition to different diameters, filaments are available in various spool sizes. A brief survey of the market reveals that the most commonly encountered sizes include 500 g, 750 g, 1 kg, 2 kg, and 3 kg.

To learn more, see our guide on Types of 3D Printer Filaments.

8. Pick a Design

Your 3D printer often comes with a USB stick containing a test model to get you started. Once you're ready to explore further, you'll want to learn where to source and possibly even create your own 3D models. For beginners, the most suitable option is to download models from various websites and 3D model archives, such as: Thingiverse®, MyMiniFactory, TurboSquid, GrabCAD®, and Cults3D. These models are typically available in STL file format, although OBJ and 3MF formats are also occasionally used. Additionally, you can even import .jpg and .png files into software like Cura to generate Lithophane models.

If you're interested in creating your own models, beginner-friendly software like TinkerCAD® is an excellent starting point. Once you've acquired sufficient knowledge and skills, you can progress to more advanced platforms like Fusion 360® or Blender.

9. Setup and Print

After creating a 3D model in design software, use specialized software that translates the model into the machine instructions script. This crucial task is accomplished through slicing software, commonly referred to as a slicer. Once you've imported your 3D model into the slicer, you have the flexibility to fine-tune various settings to align with your specific requirements. Among these settings are critical parameters like: printing speed, temperature, wall thickness, infill percentage, layer height, and many others.

The output from this process results in a G-code file. Having completed all the essential steps, it's now time to click the "Print" button and initiate the actual printing process. The duration of the printing process can vary significantly based on your configured settings and the complexity of your 3D model, with printing times typically ranging from minutes to, more commonly, several hours.

What Is a 3D Printer?

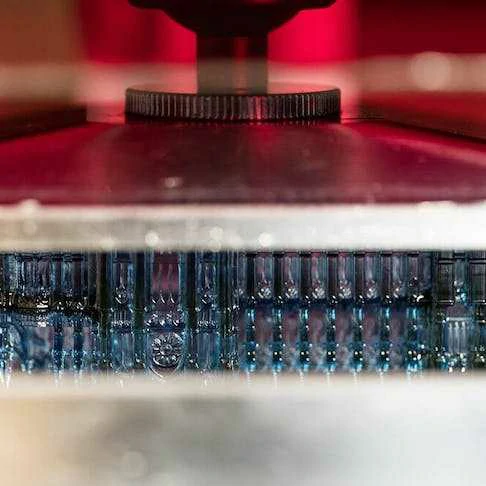

A 3D printer is a computer-controlled device that creates three-dimensional objects by adding material layer-by-layer in a process known as additive manufacturing. Unlike traditional subtractive manufacturing methods, in which the material is removed to create an object (e.g., cutting, drilling, or machining), 3D printing builds objects from the ground up.

The basic components of a 3D printer typically include: a printhead/extruder, build platform/bed, control system, filament or resin, frame and mechanics, cooling system, and bed leveling and calibration systems.

There are a lot of different 3D printer types on the market, each with its own applications, advantages, and limitations. Some popular types and methods of 3D printing include: fused deposition modeling (FDM), stereolithography (SLA), selective laser sintering (SLS), and binder jetting.

Why Does the Printer Need To Be Set Up?

Setting up a 3D printer is necessary to ensure it functions correctly, produces high-quality prints, and operates safely. For example, calibration is essential to ensure that the printer's components, like the print bed and extruder nozzle, are correctly aligned. Furthermore, bed leveling is another critical step, ensuring that the print bed is level and at the correct distance from the nozzle to facilitate proper adhesion of the first print layers. Taking the time to properly set up and calibrate your printer will lead to better results and a more satisfying 3D printing experience.

What Are Examples of 3D-Printed Items?

3D printers have been used to produce a wide variety of items across numerous industries and applications. Some examples are listed below:

- Prototypes and scale models of products and components.

- Intricate and personalized jewelry pieces, including: rings, necklaces, and earrings.

- Dental crowns, bridges, and aligners.

- Custom-fitted prosthetic limbs, orthopedic implants, and braces.

- Lightweight and complex components for aircraft and spacecraft.

- Patient-specific implants for cranial, hip, and knee surgeries.

- Detailed architectural models of buildings and landscapes.

- Custom insoles and even entire shoes.

- Anatomical models, geological formations, and historical artifacts.

- Highly detailed scale models of vehicles, buildings, and figurines for gaming and display.

How Much Does a 3D Printer Cost?

3D printers come in different shapes and sizes and also different pricing ranges, from as little as $100–200 to over $500,000. Table 1 below gives a breakdown of the expected price ranges for different classes of 3D printers:

.webp)